The department of pure metals, metal physics and technology of new materials (11-00) was established in 1974 on the basis of the vacuum metallurgy department of V.Ye. Ivanov. The founders of vacuum metallurgy and vacuum technologies at the Institute were K.D. Sinelnikov and V.Ye. Ivanov.

The first head of the department and the initiator for the construction new building for the department was the Doctor of Sciences in Physics and Mathematics, Professor G.F. Tikhinskiy.

For a long time, the department was headed by the scientist-metal physicist, Academician of NASU V.M. Azhazha. From 2008 to 2018, the department was headed by the Doctor of Technical Sciences S.D. Lavrinenko.

Click here to see the detailed history of the department creation and some facts for the vacuum metallurgy development at NSC KIPT.

The department has 5 laboratories, which employ 3 doctors and 20 candidates of sciences.

The results of work over the past 5 years were published in 378 scientific papers, 137 of them are in journals that are indexed in the leading scientometric databases (Web of Science, Scopus), 12 monographs, 14 patents, 115 reports at conferences; 1 doctoral and 4 PhD theses were prepared and defended. Click here to see the list of publications.

Main directions of work:

Ultrapure Metals

Refining processes, production, investigation of properties, development of technologies, products. The following metals were studied: magnesium, niobium, tantalum, iron, nickel, titanium, vanadium, gallium and others. In case of the need to develop a refining technology or create new alloys based on pure metals, the range of names will be expanded.

Zirconium, its alloys and hafnium

Production processes, refining, investigations on the effect of impurities on the properties, improvement of the existing manufacturing technologies and development of new ones, including equipment.

Physics and technology of nanomaterials

Physical processes for the formation of nanocrystalline, nanocomposite and single-crystal structures in special alloys based on pure metals, study of their physical and mechanical properties, improvement of the principles and methods for creating materials with a given microstructure and improved performance characteristics for use in reactor engineering, electrical engineering, instrument making, gas turbine engineering and medicine.

Beryllium physics

Refining, metal physics, technologies, products. Beryllium belongs to nuclear materials. Therefore, first of all, attention is paid to the development of technologies for its use as biological protection. Beryllium products can be used as a material for the first wall of a thermonuclear reactor.

Superconductors

Development of physical processes for the synthesis of superconductors and production technologies. Investigation of electrophysical properties for new superconducting materials.

Semiconductors

Carrying out the synthesis of semiconductor compounds, growing single crystals, obtaining products and creating sensors for radiation recording.

Major achievements:

1. The process for refining low-melting metals (Ga, Cd, Zn, Te, Pb) to the degree of purity (6N), which is carried out by a combination of vacuum heat treatment, filtration and distillation in one cycle was developed. Such a combination provides deep purification of these metals from metal and penetration impurities (N, O, C) to the level of 1 × 10-5 wt.%. Simulation of temperature conditions for growing single crystals, their electrophysical properties and the processes of metal refining was carried out.

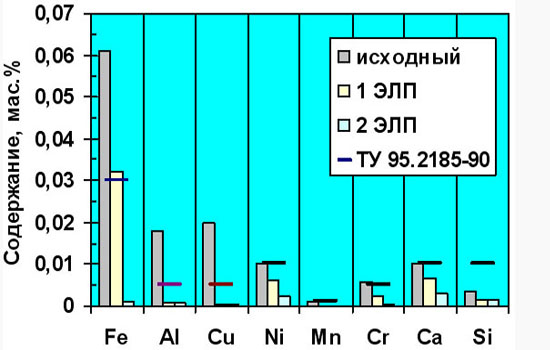

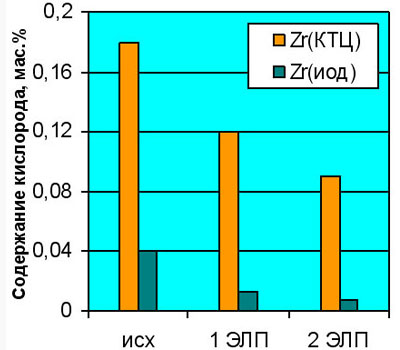

Change in the content of metallic impurities and oxygen in zirconium after two successive electron-beam melts

| No. | Element | Content, wt.% |

|---|---|---|

| 1 | Be | 99.999 |

| 2 | Cd | 99.9999 |

| 3 | Al | 99.9999 |

| 7 | Ga | 99.99999 |

| 8 | Zr | 99.99 |

| 6 | Pb | 99.9995 |

| 7 | V | 99.998 |

| 8 | Nb | 99.9996 |

| 9 | Ti | 99.99 |

| 10 | Zn | 99.9999 |

| 11 | Ta | > 99.99 |

| 12 | Cr | 99.99 |

| 13 | Mo | 99.9999 |

| 14 | W | 99.99995 |

| 15 | Re | 99.9999 |

| 16 | Ru | 99.999 |

| 17 | Os | 99.999 |

2. The technology for the manufacture of thin beryllium foils was developed and the mass production of vacuum-tight foil up to 8 μm thick was set up. The method for producing bulk metal glasses, one of the components of which is beryllium, was developed; the structure and properties of the materials obtained were studied. Prototypes of such materials were manufactured for their use as the first mirrors for plasma diagnostics.

Thin beryllium foils

Pilot cryotransformer with the winding of long wire made of high-purity beryllium (ρ = 0.055 μOhm∙cm at 77 К), suitable for use in hyperconductive systems (j ∼ 104 А/сm2)

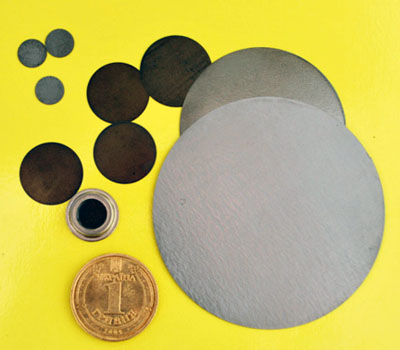

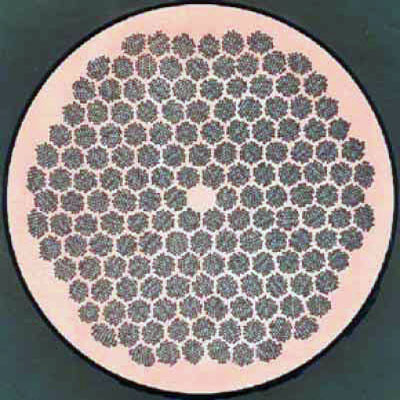

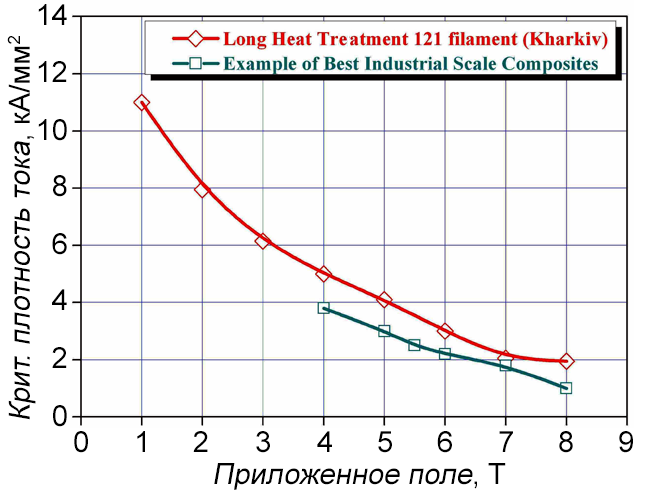

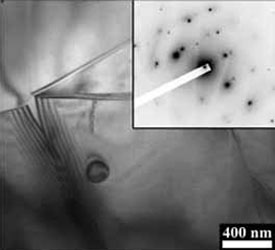

3. The new methods were developed and the modes for mechanical-thermal treatment of deformable superconductors based on niobium-titanium alloys were optimized. Multifilamentary superconductors with high current-carrying capability were created.

Multifilamentary superconductor based on Nb-Ti

Record level of current carrying capacity in Nb-Ti superconductors (4 kA/mm2, 5 T, 4.2 К)

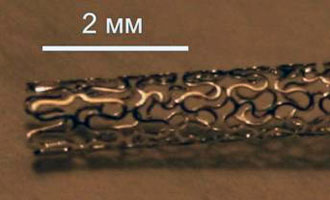

4. Magnesium of record high purity (∼ 99.9999%) was obtained; the temperature dependence for the electrical resistance of high-purity magnesium in the range of 4.5 − 300 К was studied. By refining the structure using the methods of severe deformation, the mechanical properties were significantly improved and the corrosion rate of biosoluble alloys was reduced by several orders of magnitude. Coronary stents from biosoluble magnesium alloys were manufactured and their properties were studied. New instruments and applicators for oncology were developed from the materials with increased strength and plasticity.

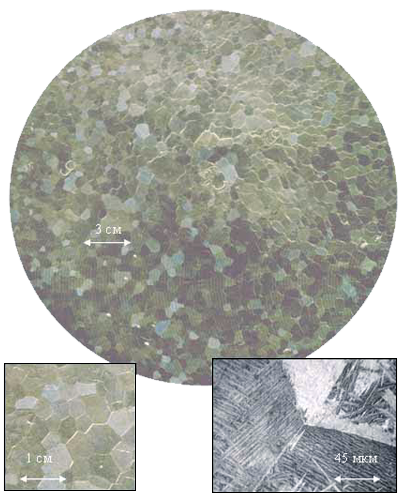

Magnesium single crystal

Coronary stent made of biosoluble magnesium alloys

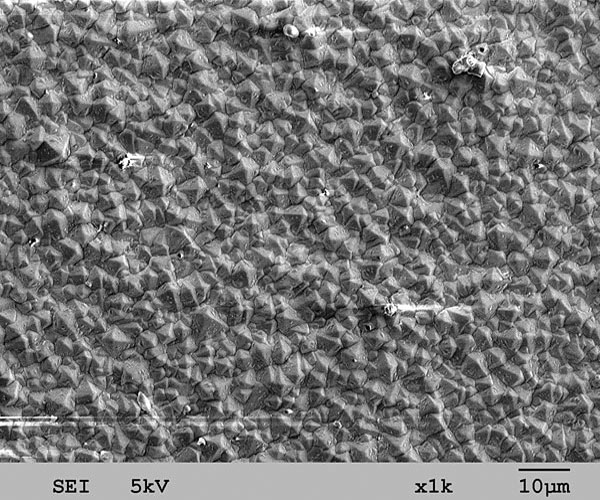

Mg-alloy structure: ultrafine-grained

structure, nano-precipitation

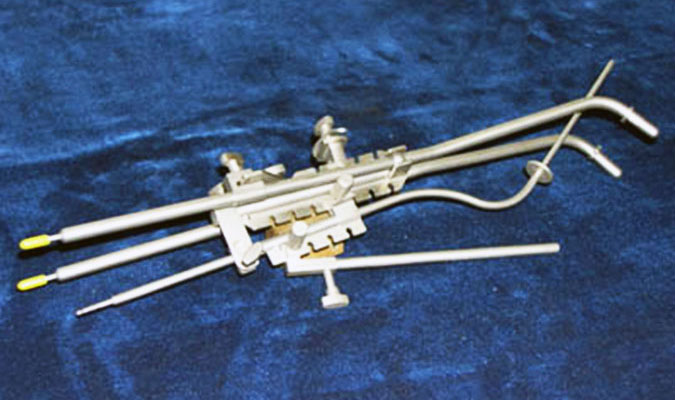

Oncology applicator (high purity ultrafine grain titanium)

Oncology needles

5. The physical fundamentals for obtaining high-purity hafnium were developed. Estimations and experimental studies for the changes in the concentration of impurities in hafnium during electron beam melting and zone recrystallization (in the electric field as well) were carried out.

6. Research on the optimization of the technological process parameters for obtaining zirconium magnesium thermal sponge at the stages of reducing zirconium tetrachloride from domestic raw materials and vacuum high-temperature treatment of rough zirconium sponge was carried out. This will make it possible to obtain zirconium in accordance with modern requirements for creating zirconium structural materials with improved properties for reactors.

7. Investigation and improvement of metal purification from impurities were carried out. Pure and ultrapure metals (Zr, Hf, Be, Mg, Cd, Zn, Te) were obtained for the production of alloys for nuclear power engineering. The physical and technological fundamentals for obtaining nuclear-pure zirconium, which meets the modern requirements of nuclear power engineering, were developed. The behavior of impurities during zirconium refining by the method of electron beam melting and the effect of zirconium purity on its properties were studied.

8. For the first time, high-purity antique lead (99.9996%) was obtained in the form of granules, which is necessary for producing low-background scintillation crystals of PbWO4.

9. The kinetics for the formation of diffusion hardened near-surface layers on sample pipes made of zirconium alloy Zr-1%Nb during chemical-thermal treatment (TCT) in controlled oxygen-containing and nitrogen media was studied. The regularities for the growth of hardened near-surface layers depending on the treatment time and environment were determined. It was also shown that due to TCT the microhardness of the inner and outer surfaces of FE tubes is significantly increased (from 2.5 to 7 times). This can significantly reduce the damage to the tubes during the operation of the FE.

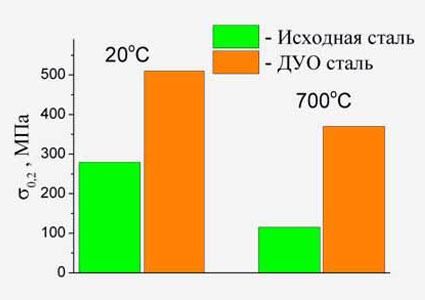

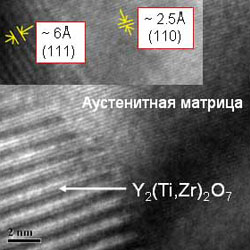

10. Technological processes for the manufacture of reactor steels modified with nanoparticles of thermostable oxides (oxide dispersion strengthened (ODS) or ODS-steels) were developed. The strength characteristics of the developed austenitic ODS-steel are 2 - 3.5 times higher, and the swelling is 5 times lower than that of the base steel X18H10T. High-entropy alloys (HEA) based on the AlCoCrCuFeNi and CoCrFeNi (Mn, V) systems were obtained and studied. High plasticity of certain compositions was determined. Research is being conducted on the effect of various treatments on their structure and properties.

| Alloy | σ0.2, MPa | σUTS, MPa | δ, % | Grain, μm |

|---|---|---|---|---|

| CoCrFeMnNi | 355 | 660 | 36 | 4.4 |

| 720 | 980 | 37 | 4.9 |

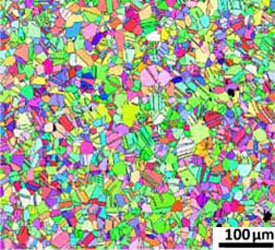

Microstructure of CoCrFeMnNi alloy, after rolling to 80% and annealing at 800°С for 1 h

Structure and mechanical properties of ODS steels X18H10T and X18H10T

11. Nanocrystalline zirconium and titanium of various purities, as well as nanostructured alloys based on them, were developed and studied. For the first time, a combination of two methods of extreme impact on metals was applied – severe plastic deformation plus subsequent cryogenic deformation.

12. The processes of refining magnesiothermal sponge zirconium of domestic production by the method of electron-beam melting were studied. This makes it possible to create the necessary preconditions for the use of magnesiothermal zirconium in the development of zirconium structural materials for NPU equipment pieces.

13. Devices based on semiconductor and gas-discharge detectors were developed for the technological processes using ionizing radiation, including NPP, the Chernobyl zone, spent fuel storage and medicine, including semiconductor detectors based on Si, GaAs, CdTe, CdZnTe and CVD diamond coatings, gas-discharge detectors based on noble gases etc.

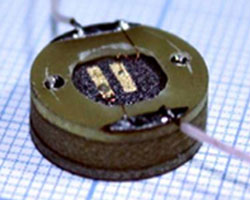

14. The prototype of gamma-radiation detection unit based on the gas-discharge linear detector and charge-sensitive preamplifier designed for radiation monitoring systems of NPPs was developed and manufactured. The detector is filled with a mixture of high-purity (99.9995%) inert gas Xe and hydrogen. The detection unit characteristics were studied under irradiation with gamma-quants of 241Am, 137Cs, 60Co isotopes.

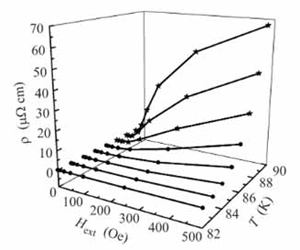

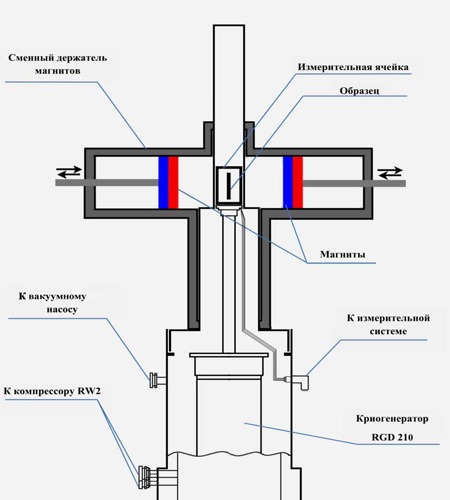

15. The complex of fundamental studies on the electrophysical and magnetic properties of granular oxide high-temperature superconductors was carried out. For the first time, the course of topological phase transitions - Berezinsky-Kosterlitz-Thoules transitions (BKT-transitions) in the Josephson medium of granular HTSC under the influence of electric and magnetic fields was determined experimentally. Works on the synthesis and investigation of the crystal structure, electromagnetic properties and radiation resistance of the new BCS-superconductor MgB2 were carried out. High-energy permanent magnets based on rare earth metals were developed.

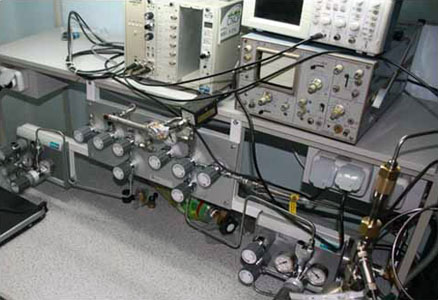

Temperature dependences for the magnetoresistance of granular HTSC YBa2Cu3O7

Measuring complex for electrophysical and magnetic properties of materials (12 - 300 К, up to 2 kOe)

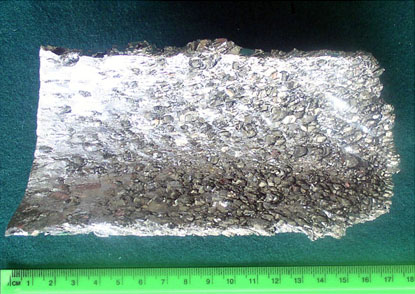

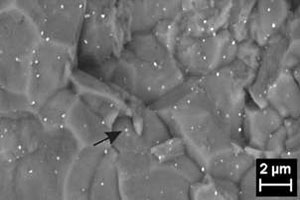

The structure of Zr-1%Nb alloy after double vacuum arc melting

16. The evolution of Zr-1%Nb alloy structure was studied at the increase of iron concentration. Small additions of iron to the alloy result in the change of its structure due to the appearance of precipitates of the Laves phase. As the iron content is increased in the Zr-1%Nb alloy, its microhardness is increased as well. High corrosion resistance of the investigated Zr-1%Nb alloys is shown. It is also shown that alloying with iron makes a significant contribution to the corrosion resistance of Zr-1%Nb alloys in reactor water.

Department structure

- Research Laboratory of Zirconium Physics and Pure Metal Technologies.

The main scientific areas of the laboratory are vacuum and high-vacuum metallurgy; physics and materials science of pure and ultrapure metals and alloys with special physical properties; technological processes for the production of pure metals and structural materials for reactor construction, electronics and other areas of technology. Among the fundamental results of the laboratory's scientific research, it is also research and development of new methods of refining of metals, obtaining a number of metals of record purity and determining previously unknown physical properties, investigation of the relationship between the chemical composition, structure and physical properties of metals and alloys, and work on the synthesis of structural materials for nuclear energy.

Laboratory employees participate in the development of industrial technologies for obtaining of nuclear-grade zirconium, hafnium, and calcium, of technologies for refining niobium, gallium, and scandium, and in the creation of new heterodyne materials and materials for medicine. Also, the group of physical materials science of functional ceramic materials conducts fundamental research on materials with special electrophysical, magnetic, elastic and other properties in a wide temperature range, studies of the magnitude and directions of the external magnetic field, transport current density, etc., used or that may find application in the nuclear power industry of Ukraine for the transportation, conversion and accumulation of energy of nuclear power plants, as well as the detection of various types of radiation. The semiconductor materials group is investigating the refining processes of low-melting metals (Ga, Cd, Zn, Te, Pb, etc.) to the purity level (6N) by combining vacuum heat treatment, filtration, and distillation in a single cycle. These technologies represent a step-by-step purification of volatile impurities with filtration, as well as purification of highly volatile impurities using a getter filter, which provides a deeper purification of metals from metal impurities, including from introduced impurities (N, O, C) to the level of 1 × 10−5 wt.%; modeling of temperature conditions for growing of single crystals, their electrophysical properties, and metal refining processes is also performed.

- Research Laboratory of Electrophysical Materials and Technical Superconductors.

The laboratory conducts research into the physical processes of forming of nanocrystalline, nanocomposite and single-crystalline structures in special alloys based on pure metals, studies of their physical and mechanical properties, and improves the principles and methods of creating materials with a given microstructure and increased performance characteristics for use in reactor construction, electrical engineering, instrument making, gas turbine construction and medicine. Also, samples of multicomponent and high-entropy alloys of a wide range of chemical compositions are manufactured and studied for various economic needs. Magnetic materials for medical equipment are developed and studied.

- Scientific and Research Laboratory of Metal Physics and Technology of Beryllium and Construction Materials.

Work is being carried out on the creation of structural grades of beryllium based on powder and cast materials. A technology and equipment have been developed for obtaining of spherical beryllium powders with a metastable structure by the melt spraying method, a technology for obtaining of vacuum-tight foils and thin wires has been developed, and the hyperconductivity of beryllium has been investigated.

In addition to beryllium materials, the laboratory conducts research on developing of technologies for producing of new structural materials. The processes of formation of structural characteristics and their influence on the physical, mechanical and radiation properties of materials based on zirconium and hafnium for nuclear and thermonuclear energy are studied.

- Research Laboratory of the Physical Foundations of the Creation of New Beryllium Materials.

Research is being conducted into the physical nature of plastic flow and fracture of light metals and alloys; development of new methods for plasticizing of metals and alloys used in nuclear technology and medicine; development of new methods for intensive deformation of materials; development of new materials with high strength and plasticity (beryllium, magnesium, etc.); study of the relationship between mechanical properties and structural factors; development of new methods for studying of plastic deformation and fracture of metals and alloys, including acoustic emission, fracture toughness, impact toughness with separation of deformation work and fracture work.

- Research laboratory for new technological solutions.

The directions of the laboratory are: development of devices based on semiconductor and gas-discharge detectors for the technological processes using ionizing radiation, including nuclear power plants, the Chernobyl zone, spent fuel storages and medicine; research and manufacture of semiconductor detectors based on Si, GaAs, CdTe, CdZnTe and CVD diamond coatings; research and manufacture of gas-discharge detectors based on noble gases; development and manufacture of various devices for detecting ionizing radiation.

Publications

| 1. | G.A. Salishchev, M.A. Tikhonovsky, D.G. Shaysultanov, N.D. Stepanov, A.V. Kuznetsov, I.V. Kolodiy, A.S. Tortika, O.N. Senkov. Effect of Mn and V on Structure and Mechanical Properties of High-entropy Alloys Based on FeCrCoNi System. Journal of Alloys and Compounds. 2014, No. 591, р. 11 - 21. |

|---|---|

| 2. | N. Stepanov, M. Tikhonovsky, N. Yurchenko, D. Zyabkin, M. Klimova, S. Zherebtsov, A. Efimov, G. Salishchev. Effect of Cryo-deformation on Structure and Properties of CoCrFeNiMn High-entropy Alloy. Intermetallics. April 2015, v. 59, p. 8 - 17. |

| 3. | V.V. Derevyanko, T.V. Sukhareva, V.A. Finkel, M.S. Sunhurov, Yu.N. Shakhov. Phase Transitions in a MgB2 Granular BCS Superconductor in Weak Magnetic Fields. Physics of the Solid State. 2017, 59(2), p. 229 - 235. |

| 4. | Г.П. Ковтун, Р.С. Бойко, Ф.А. Даневич, Б.Н. Кропивянский, В.М. Мокина, Т.С. Потина, Д.А. Солопихин, И.А. Тупицына, А.П. Щербань, В.Н. Шлегель. Производство и свойства низкофоновых сцинтилляторов вольфраматов кадмия и свинца для поиска двойного бета-распада. Ядерна фізика та енергетика. 2014, т. 15, № 1, с. 92 - 100. |

| 5. | Arun S. Wagh, S.Yu. Sayenko, A.N. Dovbnya, V.A. Shkuropatenko, R.V. Tarasov, A.V. Rybka, A.A. Zakharchenko. Durability and Shielding Performance of Borated Ceramicrete Coatings in Beta and Gamma Radiation Fields. Journal of Nuclear Materials. July 2015, v. 462, p. 165 - 172. |

| 6. | Iu. Nasiekaa, V. Strelchuk, M. Boyko, V. Voevodin, A. Vierovkin, A. Rybka, V. Kutniy, S. Dudnik, V. Gritsina, O. Opalev, V. Strel’nitskij. Raman and Photoluminescence Characterization of Diamond Films for Radiation Detectors. Sensors and Actuators A: Physical. 2015, v. 223, p. 18 - 23. |

| 7. | О.В. Єфімов, М.М. Пилипенко, Т.В. Потаніна, В.Л. Каверцев, Т.А. Гаркуша. Реактори і парогенератори енергоблоків АЕС: схеми, процеси, матеріали, конструкції, моделі. Монографія. Харків: ТОВ «В справі». 2017, 420 с. |

| 8. | Е.D. Tabachnikova, А.V. Podolskiy, M.O. Laktionova, N.A. Bereznaia, M.A. Tikhonovsky, A.S. Tortika. Mechanical Properties of the CoCrFeNiMnVx High Entropy Alloys in Temperature Range 4.2–300 K. Journal of Alloys and Compounds. 2017, v. 698, p. 501 - 509. |

| 9. | N.D. Stepanov, N.Y. Yurchenko, S.V. Zherebtsov, M.A. Tikhonovsky, G.A. Salishchev. Aging Behavior of the HfNbTaTiZr High Entropy Alloy. Materials Letters. 2018, v. 211, р. 87 - 90. |

| 10. | Jongun Moon, Yuanshen Qi, Elena Tabachnikova, Yuri Estrin, Won-Mi Choi, Soo-Hyun Joo, Byeong-oo Lee, Aleksey Podolskiy, Mikhail Tikhonovsky, Hyoung Seop Kim. Deformation-induced Phase Transformation of Co20Cr26 High-entropy Alloy During High-pressure Torsion at 77 K. Materials Letters. 2017, v. 202, p. 86 - 88. |

| 11. | V. Bovda, I. Guk, S. Kononenko, V. Lyashchenko, A. Mytsykov, L. Onischenko. Sm-Co Based Magnetic System for 10 Mev Technological Electron Accelerator LU-10M. East European Journal of Physics. 2018, v. 5(3), p. 68 - 74. |

| 12. | Е.И. Кузнецова, С.В. Сударева, Т.П. Криницина, Ю.В. Блинова, Е.П. Романов, Ю.Н. Акшенцев, М.В. Дегтярев, М.А. Тихоновский. Механизм образования и особенности структуры массивных образцов соединения MgB2. ФММ. 2014, 115(2), с. 186 - 197. |

| 13. | V. Ovcharenko, A. Kuprin, G. Tolmachova, I. Kolodiy, A. Gilewicz, O. Lupicka, J. Rochowicz, B. Warcholinski. Deposition of chromium nitride coatings using vacuum arc plasma in increased negative substrate bias voltage. Vacuum. 2015, v. 117, p. 27 - 34. |

| 14. | А.В. Бабун, К.В. Ковтун. Порошковая металлургия бериллия. Монография. Харьков, «Синтекс». 2016, 224 с. |

| 15. | A.S. Bakai, K.V. Kovtun, L.N. Davydov. Combined Effect of Irradiation and Molten Fluoride Salt on Ni-Based Alloys. Thorium Energy for the World. Editor by Revol JP Springer. 2016, p. 393 - 394. |

| 16. | V.S. Trush, V.M. Fedirko, O.H. Luk’yanenko, K.V. Kovtun. Optimization of the Medium of Thermal Treatment of GFE-1 Hafnium Alloy. Materials Science. September 2017, v. 53, No. 2, p. 194 - 199. |

| 17. | Arun S. Wagh, S.Yu. Sayenko, V.A. Shkuropatenko, R.V. Tarasov, M.P. Dykiy, Y.O. Svitlychniy, E.A. Ulybkina. Cesium Immobilization in Struvite Structure. Journal of Hazardous Materials. 2016, v. 302, p. 241 - 249. |

| 18. | А.П. Щербань, Г.П. Ковтун, Ю.В. Горбенко, Д.А. Солопихин, Л.А. Пироженко. Получение высокочистых гранулированных металлов кадмия, цинка и свинца. Технология и конструирование в электронной аппаратуре. 2017, № 1 - 2, с. 55 — 60. |

| 19. | И. Папиров, П. Стоев, А. Николаенко, Ю. Тузов. Влияние структурных факторов на прочностные и вязкостные характеристики бериллия. Монография. Lambert Academic Publishing, Saarbrucken. 2014, 450 с. |

| 20. | И.И. Папиров, П.И. Стоев. Изучение акустической эмиссии материалов реакторостроеня. Монография. Харьков, Национальный научный центр «Харьковский физико-технический институт»., 2015, 60 с. |

| 21. | П.И. Стоев, С.В. Литовченко, И.А. Гирка. Химическая коррозия металлов. Монография. ХНУ. 2019. |

| 22. | И.И. Папиров, П.И. Стоев, Т.Г. Емлянинова, А.А. Николаенко. Исследование акустической эмиссии при деформации магниевого сплава WE43. Сучасні проблеми фізики металів і металічних систем. Киев, 2016, с. 170. |

| 23. | M.S. Sunhurov, V.V. Derevyanko, T.V. Sukhareva, V.A. Finkel. Phase Transitions for MgB2 Granular BCS-superconductor in Weak Magnetic Fields. IEEE Xplore Digital Library. 2016, YSF-2016, p. 92 - 95. |

| 24. | M.S. Sunhurov, T.V. Sukhareva, V.A. Finkel. Investigations and Developments of the New Type Strongly Textured Paramagnetic Ni-W Substrates with Buffer Coating for Creating the Second Generation High Temperature Superconductors. IEEE Xplore Digital Library. 2016, YSF-2016, p. 96 - 99. |

| 25. | В.В. Деревянко, М.С. Сунгуров, Т.В. Сухарева, В.А. Финкель, Ю.Н. Шахов. Фазовые переходы в гранулярном BCS-сверхпроводнике MgB2 в слабых магнитных полях. Физика твёрдого тела. 2017, т. 59, № 2, c. 223 - 229. |

| 26. | M.S. Sunhurov, S.A. Leonov, T.V. Sukhareva, V.V. Derevyanko, V.A. Finkel, Yu.N. Shakhov. Research of the Processes of Texture Formation in the System «NiW Substrate and TiN Coating» and Creating of the New Type Textured Paramagnetic Substrates for HTS based on YBa2Cu3O7. Functional Materials. 2017, v. 24, № 1, p. 63 - 67. |

| 27. | M.S. Sunhurov, V.V. Derevyanko, S.A. Leonov, T.V. Sukhareva, V.A. Finkel, Yu.N. Shakhov. Structural Aspects of the Phase and Texture Formation Processes in Thin-layer Ni-W/TiN Systems, Perspective for Creating High-temperature Superconductors of the Second Generation. Functional Materials. 2017, v. 24, № 3, p. 353 - 359. |

| 28. | V.V. Derevyanko, V.A. Finkel, T.V. Sukhareva. Phase Transitions and Vortex Structure Evolution in Two-level High-temperature Granular Superconductor YBa2Cu3O7-σ Under Temperature and Magnetic Field. Physics of the Solid State. 2017, v. 59, No. 8, p. 1492 - 1500. |

| 29. | V.V. Derevyanko, M.S. Sunhurov, T.V. Sukhareva, V.A. Finkel, Yu.N. Shakhov. Investigation of Crystal Structure and Electrophysical Properties of Ni-W Alloys: Percolation Processes. IEEE Xplore Digital Library. 2017, YSF-2017, p. 167 - 170. |

| 30. | V.V. Derevyanko, V.A. Finkel, T.V. Sukhareva, M.S. Sunhurov. Evolution of Vortex Structure of Two-Level Granular High Temperature Superconductor YBa2Cu3O7-σ under Influnece of Temperature, Magnetic Field and Transport Current. IEEE Xplore Digital Library. 2017, YSF-2017, p. 171 - 174. |

| 31. | Т.В. Сухарева, В.А. Финкель. Фазовый переход Березинского–Костерлица–Таулесcа в джозефсоновской среде двухуровневого гранулярного высокотемпературного сверхпроводника YBa2Cu3O7-σ. ФНТ. 2018, т. 44, № 3, c. 258 - 263. |

| 32. | В.В. Деревянко, Т.В. Сухарева, В.А. Финкель. Влияние температуры, внешнего магнитного поля и транспортного тока на электрофизические свойства, процессы эволюции вихревой структуры и фазовые переходы в подсистемах сверхпроводящих гранул и «слабых связей» гранулярного двухуровневого высокотемпературного сверхпроводника YBa2Cu3O7-σ. ФТТ. 2018, т. 60, в. 3, с. 465 - 475. |

| 33. | V.V. Derevyanko, M.S. Sunhurov, T.V. Sukhareva, V.A. Finkel, Yu.N. Shakhov. Crystal Structure and Electrical Resistance of Ni-W Alloys. Functional Materials. 2018, v. 25, № 1, p. 048 - 053. |

| 34. | В.В. Деревянко, М.С. Сунгуров, Т.В. Сухарева, В.А. Финкель, Ю.Н. Шахов. Особенности влияния состава и кристаллической структуры на поведение электрофизических свойств сплавов системы Ni(1-x)Wx при низких температурах. ФТТ. 2018, т. 60, в. 10, с. 1896 - 1900. |

| 35. | М.О. Азаренков, І.М. Неклюдов, В.М. Береснев, В.М. Воєводін, О.Д. Погребняк, О.В. Соболь, Г.П. Ковтун, В.Г. Удовицький, С.В. Литовченко, П.В. Турбін, В.О. Чишкала. Наноматеріали і нанотехнології. Навчальний посібник. Харків: ХНУ ім. В.Н. Каразіна. 2014, 316 с. |

| 36. | А.И. Кравченко. Разработка перспективных схем зонной дистилляции. Перспективные материалы. 2014, № 7, с. 68 - 72. |

| 37. | А.И. Кравченко. Зависимость эффективного коэффициента разделения в некоторых металлических системах основа-примесь от степени перегонки. Неорганические материалы. 2015, т. 51, № 2, с. 146 - 147. |

| 38. | А.И. Кравченко. Расчёт дистилляционного рафинирования вещества с легколетучей и труднолетучей примесями. Неорганические материалы. 2018, т. 54, № 5, с. 520 - 522. |

| 39. | A.P. Shcherban, O.A. Datsenko, G.P. Kovtun. Construction of Solidus Lines of Binary Metal Systems Having a Low Solubility of Components in the Solid Phase. Open Journal of Metal. September 23, 2014, v. 4, No. 3. |

| 40. | Г.П. Ковтун, А.П. Щербань, Д.А. Солопихин. Глубокое рафинирование легкоплавких металлов дистилляцией в вакууме. Коллективная монография «Высокочистые вещества». Издательство: Научный мир. 2018, гл. 21, с. 496 - 516. |

| 41. | L. Davydov, P. Fochuk, A. Zakharchenko, V. Kutny, A. Rybka, N. Kovalenko, S. Sulima, I. Terzin, A. Gerasimenko, M. Kosmyna, V. Sklyarchuk, O. Kopach, O. Panchuk, A. Pudov, A.E. Bolotnikov, R.B. James. Improving and Characterizing the Quality of (Cd,Zn)Te Crystals for Detecting Gamma Radiation. IEEE Transactions of the Nuclear Science. 2015, v. 62, No. 4, p. 1779 - 1784. |

| 42. | A.O. Pudov, A.S. Abyzov, S.A. Sokolov, L.N. Davydov, A.V. Rybka, V.E. Kutny, S.I. Melnikov, G.A. Kholomyeyev, S.A. Leonov, A.A. Turchin. Measurements and Modeling of Charge Carrier Lifetime in Compressed Xenon. Nuclear Inst. and Methods in Physics Research, A. 2018, v. 892, p. 98 - 105. |

| 43. | V. Bilous, V. Borysenko, V. Voyevodin, S. Didenko, M. Ilchenko, O. Rybka, O. Kuznetsov, Y. Plisak. Layered Metal Composites: Newest Generation of Radiation-Protective Materials. Journal of Materials Science and Chemical Engineering. 2014, 2, p. 6 - 11. |

| 44. | В.Е. Кутний, А.В. Рыбка, Л.Н. Давыдов, А.А. Захарченко, Д.В. Кутний, А.С. Абызов Детекторы ионизирующих излучений на основе теллурида кадмия-цинка. Харьков: Тип. Мадрид. 2021, 352 стр. |

Employees

PYLYPENKO MYKOLA MYKOLAYOVYCH

Head of the Department of “Pure Metals, Metal Physics and Technologies of New Materials”

Doctor of Technical Sciences, specialty 01.04.07 – Solid State Physics

Senior Researcher in the specialty 01.04.13 – Physics of Metals

e-mail: mpylypenko@kipt.kharkov.ua

Field of scientific interests:

vacuum metallurgy, solid state physics, production of pure and ultrapure metals, materials science. Research into the refining processes of refractory and chemically active metals, development of the fundamentals of technologies for the production of ultrapure metals and alloys based on them for nuclear power and other sectors of the national economy. Specialist in the field of metal physics, vacuum metallurgy and physical materials science of rare and refractory metals (including Zr, Hf, Ta, V, Fe, Ni, Mg, etc.). With his participation, the physical and technological foundations of metal refining in high and ultrahigh vacuum were developed, the use of ultrahigh vacuum pumping equipment and the method of mass spectrometric control of the gas environment during heat treatment and melting of metals in vacuum were substantiated.

SOLOPIKHIN DMYTRO OLEKSIYOVYCH

Head of the Research Laboratory “Zirconium Physics and Pure Metal Technologies”

Candidate of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

e-mail: solopikhin_d@ukr.net

Field of scientific interests:

processes of deep refining of substances, creation of new materials based on them and study of their properties. Development of new effective physical methods and devices for refining metals and study of the properties of the obtained ultrapure metals and semiconductor, scintillation and functional materials based on them.

TYKHONOVSKYY MYKHAYLO ANDRIYOVYCH

Head of the Laboratory of “Electrophysical Materials and Technical Superconductors”

Candidate of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

e-mail: tikhonovsky@kipt.kharkov.ua

Field of scientific interests:

development of new materials, including steels and high-entropy alloys for nuclear power, creation of nanostructured materials through intense plastic deformations and mechanical fusion, study of phase and structure formation processes under various influences on materials and physical and mechanical properties of the created materials. Research profile – solid-state physics and physical materials science.

KUTNIY VLODYMYR EVDOKYMOVYCH

Head of the Laboratory “New Technological Developments”

Candidate of Technical Sciences in specialty 05.16.01 – Metal Science and Heat Treatment of Metals

Senior Researcher

e-mail: kutny@kipt.kharkov.ua

Field of scientific interests:

research of electrophysical characteristics and development of semiconductor and gas-filled detectors for measuring ionizing radiation.

KOVTUN KOSTYANTYN VASYLOVYCH

Director of the State Enterprise “STC “Beryllium” of the NAS of Ukraine, Scientific Head of the Laboratory “Materials Science and Technology of Beryllium and Structural Materials”

Candidate of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

Senior Researcher

Laureate of the State Prize of Ukraine in the field of science and technology, 2018.

e-mail: kkovtun@kipt.kharkov.ua

Field of scientific interests:

Refining processes of low-melting metals; synthesis, study of the crystal structure, electromagnetic properties and radiation resistance of new BCS-superconductors; methods of forming of ultra-fine-grained and nanocrystalline structures in reactor materials (zirconium and its alloys, niobium, tantalum) by intensive plastic deformation.

STOYEV PETRO ILYCH

Leading Researcher

Doctor of Physical and Mathematical Sciences in specialty 01.04.13 – Physics of Metals

Professor

e-mail: stoev@kipt.kharkov.ua; petr.stoev@gmail.com

Field of scientific interests:

research of structural and mechanical properties of new constructional materials: mechanical and viscous characteristics, acoustic emission.

KONDRYK OLEKSANDR IVANOVYCH

Researcher

Candidate of Physical and Mathematical Sciences, specialty 01.04.07 – Solid State Physics

e-mail: alex.kondrik2017@gmail.com

Field of scientific interests:

Research using computer modeling of the electrophysical and detector properties of CdTe, CdZnTe, CdMnTe, CdMgTe depending on the impurity and defect composition and after ionizing irradiation.

VELYKODNYY OLEKSIY MYKOLAYOVYCH

Senior Researcher

Candidate of Physical and Mathematical Sciences in specialty 01.04.13 – Physics of Metals

Senior Researcher

Laureate of the State Prize of Ukraine in the field of science and technology, 2018.

e-mail: velikodnyi@kipt.kharkov.ua

Field of scientific interests:

research of the influence of the features of the electronic spectrum on the mechanical properties of alloys. Creation of promising nanostructured structural materials for nuclear energy. Development and implementation of surgical instruments for removing of foreign bodies in the treatment of gunshot wounds.

KUTNII KSENIYA VOLODYMYRIVNA

Senior Researcher

Candidate of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

e-mail: kutnjakv1984@nas.gov.ua

Field of scientific interests:

development of nanomaterials and ultrafine-grained materials based on pure titanium and magnesium alloys for medical applications using various types of intense plastic deformation in conjunction with heat treatment and cryogenic deformation.

KYSLYAK IHOR FILIPOVYCH

Senior Researcher

Candidate of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

Docent

e-mail: kislyakip1952@nas.gov.ua

Field of scientific interests:

studying the effect of intense plastic deformations by deposition-extrusion-drawing together with quasi-hydroextrusion at room and cryogenic (liquid nitrogen) temperatures on the structure, mechanical properties and acoustic emission of titanium iodide, research on high-entropy alloys (HEAs) and dispersion-strengthened oxide-based high-entropy alloys (DSO-HEAs).

AJAZHA ROMAN VOLODYMYROVYCH

Senior Researcher

Candidate of Technical Sciences in specialty 01.04.07 – Solid State Physics

Field of scientific interests:

research of the physical processes of forming of structural characteristics and their influence on the physical and mechanical properties of materials based on Be, Zr, and Hf.

BOVDA VIRA OLEKSANDRIVNA

Senior Researcher

Candidate of Technical Sciences in specialty 01.04.07 – Solid State Physics

e-mail: vera.bovda@gmail.com

Field of scientific interests:

research of the structural and magnetic properties of magnetically hard materials of various classes based on transition and rare earth metals.

SHOKUROV VOLODYMYR SERGIYOVYCH

Senior Researcher

Candidate of Technical Sciences in specialty 01.04.07 – Solid State Physics

Field of scientific interests:

development of materials for nuclear and space technology, research and production of plastic, superplastic and ultrapure materials. Specialist in the field of physics of plastic deformation of metals, materials and devices for medicine.

PIKALOV ANATOLIY IVANOVYCH

Senior Researcher

Candidate of Technical Sciences in specialty 01.04.07 – Solid State Physics

Field of scientific interests:

development of materials for nuclear and space technology, research and production of plastic, superplastic and ultrapure materials. Specialist in the field of physics of plastic deformation of metals, materials and devices for medicine.

SUKHAREVA TETIANA VITALIIVNA

Senior Researcher

Doctor of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

Senior Researcher in the specialty 01.04.07 – Solid State Physics

Member of the Scientific Council at the Department of Physics and Astronomy of the National Academy of Sciences of Ukraine on the problem «Physics of the metallic state» (section «Transport phenomena in metallic materials»)

e-mail: t.sukhareva.2003@gmail.com, sukhareva@kipt.kharkov.ua

Field of scientific interests:

solid state physics, superconductivity, magnetism, optics and laser physics, materials science, physics of radiation phenomena. Fundamental research of materials with special electrophysical, magnetic, elastic and other properties in a wide range of temperatures, the magnitude and direction of the external magnetic field, the density of the transport current, used or could find application in the nuclear power industry of Ukraine for the transportation, transformation and accumulation of nuclear power, as well as detection of various types of radiation.

Activities outside the NSC KIPT:

member of the editorial board of the journal «Functional materials».

KRAVCHENKO OLEKSANDR IVANOVYCH

Senior Researcher

Candidate of Technical Sciences in specialty 01.04.07 – Solid State Physics

Senior Researcher

e-mail: alex@krawa.net

Field of scientific interests:

development of issues of theory and practice of highly pure substances obtaining through distillation, sublimation and crystallization.

SHCHERBAN OLEKSIY PETROVYCH

Senior Researcher

Candidate of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

Senior Researcher

Laureate of the State Prize of Ukraine in the field of science and technology, 2016.

e-mail: shcherban@kipt.kharkov.ua

Field of scientific interests:

studying the patterns of impurity behavior during distillation and crystallization purification of metals (including isotope-enriched ones), developing of new effective processes and devices for obtaining high-purity metals and substances, and studying their properties.

MALYKHIN DMYTRO GEORGIYOVYCH

Senior Researcher

Candidate of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

e-mail: dmitr.malykhin@gmail.com

Field of scientific interests:

reactor materials science, X-ray analysis of the structure and texture of metals and alloys.

RYBKA OLEKSANDR VIKTOROVYCH

Senior Researcher

Candidate of Physical and Mathematical Sciences, specialty 01.04.21 – Radiation Physics and Nuclear Safety

Senior Researcher

e-mail: rybka@kipt.kharkov.ua

Field of scientific interests:

research of electrophysical characteristics and development of semiconductor and gas-filled detectors for measuring ionizing radiation.

PUDOV OLEKSIY OLEHOVYCH

Senior Researcher

Candidate of Physical and Mathematical Sciences in specialty 01.04.13 – Physics of Metals

e-mail: pudov@kipt.kharkov.ua

Field of scientific interests:

research into electrophysical characteristics and development of semiconductor and gas-filled detectors for measuring ionizing radiation.

KOZHEVNIKOV OLEG EVGENOVYCH

Researcher

Candidate of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

e-mail: kozhevnikov@kipt.kharkov.ua

Field of scientific interests:

research of the processes of refining metals (hafnium, zirconium, molybdenum, niobium, nickel, gallium) using electron beam and zone melting methods in vacuum in order to obtain highly pure metal samples; research of the physical and mechanical properties of the obtained materials.

DROBYSHEVSKA HANNA OLEKSANDRIVNA

Senior Researcher

Candidate of Technical Sciences in specialty 01.04.07 – Solid State Physics

e-mail: danna11@kipt.kharkov.ua

Field of scientific interests:

research of the influence of the amount of iron in the Zr-1% Nb alloy on its structure, physical, mechanical and corrosion properties, as well as research of the influence of radiation exposure on zirconium alloys.