The main direction of the department's work is the development and investigation of the processes, technologies and materials for the compaction and immobilization of radioactive waste (RW).

The department carries out research on the physical substantiation and development of the technologies for immobilization (inclusion in the protective form) of radioactive waste. The technologies being developed for the creation of protective materials are based on the processes of sintering of powder materials, including sintering under pressure (hot pressing, hot isostatic pressing). The use of these technologies makes it possible to obtain protective ceramic materials characterized by high radiation and corrosion resistance.

The department consists of 5 groups, which include 14 researchers. Among them there are 1 Doctor of Sciences and 3 PhDs.

The experimental results have been published in more than 500 publications. Click here to see a more detailed list.

Main directions of work

Main directions of activity:

- development of scientific foundations for the methods and processes of compaction and immobilization of radioactive waste into protective ceramic and glass-ceramic forms for temporary storage and final geological disposal;

- materials science research on the production of high-strength and radiation-resistant ceramics for functional purposes.

Research programs:

- "Departmental order of NAS for scientific research on nuclear science and technology of NSC KIPT";

- targeted complex program of scientific research for NAS of Ukraine "Scientific and technical support for the development of nuclear power industry and the use of radiation technologies in the economy sectors";

- targeted complex program of scientific research for NAS of Ukraine "Scientific support for the development of the nuclear power complex and promising nuclear technologies";

- targeted complex program of scientific research for NAS of Ukraine "Nuclear and Radiation Technologies for the Energy Sector and Public Needs".

Major achievements

Under the cooperation with the Argonne National Laboratory (USA), the manufacturing process for the phosphate ceramics KMgPO4 · 6H2O was developed for immobilization of radioactive waste. Complex testing of the obtained materials for strength, corrosion and radiation resistance was carried out and positive results were obtained. Based on the results of work, the papers were published in the leading foreign journals: "Journal of Nuclear Materials" and "Journal of Hazardous Meterials" (Elsevier).

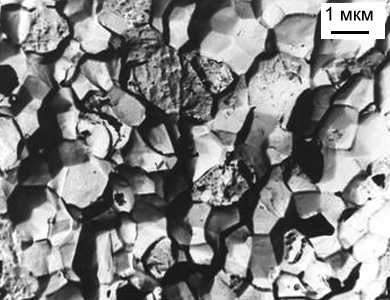

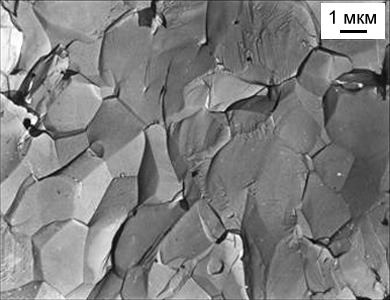

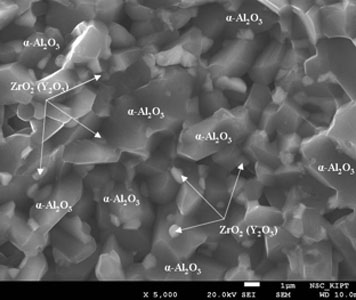

The method for obtaining transformation-strengthened ceramics based on Al2O3 and ZrO2 was developed using nanopowders as the initial components, as well as special dispersing additives. The developed technology makes it possible to obtain thin-walled products, including those of complex configuration and uniform distribution of properties throughout the entire volume of the sample. The obtained ceramics is characterized by high values of ultimate strength in bending and crack resistance, which is similar to the imported counterparts. The results of work were published in the leading journals "Ceramics International" (Elsevier).

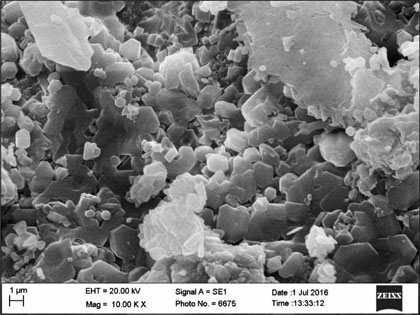

In order to develop an Accident Tolerant Fuel (ATF), the technology for producing dispersion-strengthened composite ceramics based on SiC was created. High-density SiC-ceramics with improved mechanical and corrosive properties was produced using high-speed hot pressing of finely dispersed SiC powder doped with metallic Cr.

International projects:

- Partner project under the IPP program (Contract ANL-T2-0248UA, STCU P-547) “New protective barriers for the containment and immobilization of radioactive materials”, partners: Argonne National Laboratory (ANL) and Boron Products LLC (USA), 2012 - 2014.

- Partner project (STCU P-680) "Chemically Bonded Silico-Phosphate Sprayable Ceramics". Partner: Ceramicoat International Inc. (Canada), 2016.

In recent years, there appeared a new direction of research in relation to the work plan of Euratom on the European Joint Program in Radioactive Waste Management and Disposal (EJP1), namely, the study of the behavior for compacted bentonite clay (as a buffer material in the system for geological removal of RW) at different temperatures (100 - 150°С). The participation of the ISSPMT team in the consortium of executors for this program has been approved and the funding has been provided for 2019 - 2024.

Together with the Argonne National Laboratory and the Superior Graphite company (USA), the unit for consolidation of powdered molds for ceramics of various compositions was developed, manufactured and put into operation both in the protective atmosphere of inert gases and in vacuum (≥ 1.0 Pa).

Acceptance of the electrical consolidation unit for commissioning within the STCU Р-154 project.

From left to right:

S.Yu. Sayenko (work coordinator from NSC KIPT),

Dr. Sami Gopalsami (collaborator from ANL, USA),

M.V. Savoskin (Donetsk Institute of Physics and Technology).

Obtaining functional and composite nanostructured materials:

- research and methodological recommendations for obtaining ultradispersed (including nanosized) powders for the manufacture of functional ceramics based on ZrO2, Al2O3, MgO, Y2O3 and composites on their basis;

- investigation of the methods for molding ceramic blanks from ultradispersed powders by slip casting and pressing;

- manufacture of ceramic products for various purposes and configurations that are similar in their physical and mechanical properties to foreign analogues.

Equipment for the manufacture and sintering of high-strength oxide ceramics.

Isolation of RW - development of new protective radiation- and corrosion-resistant ceramic materials

For reliable storage of RW, the protective oxide ceramics based on Al2O3 and modified with fine particles of stabilized zirconium oxide ZrO2(Y2O3) was developed. The development of finely dispersed structure with the uniformly distributed ZrO2(Y2O3) additive in the Al2O3 structure made it possible to improve the strength characteristics of ceramics:

- crack resistance - by 30%;

- resistance to bending - by 25%;

- hardness - by 10%.

A pilot batch of protective containers was manufactured for the Ukrainian State Association "Radon".

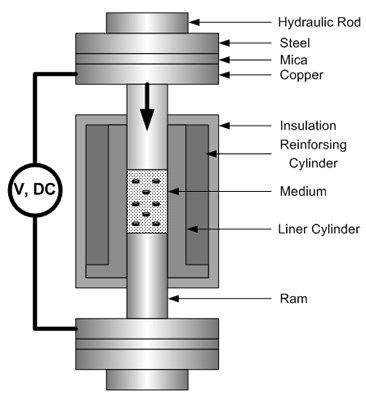

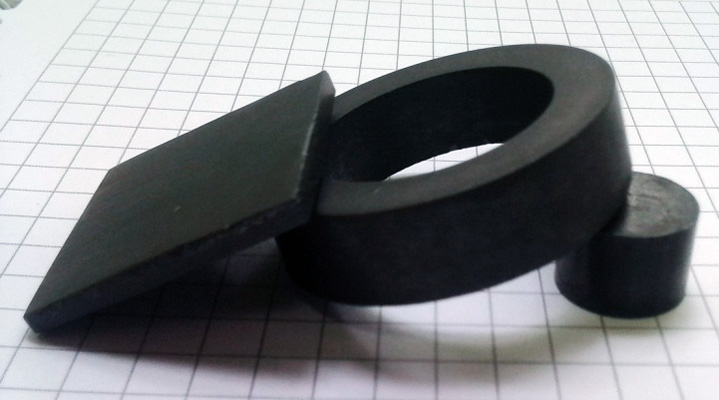

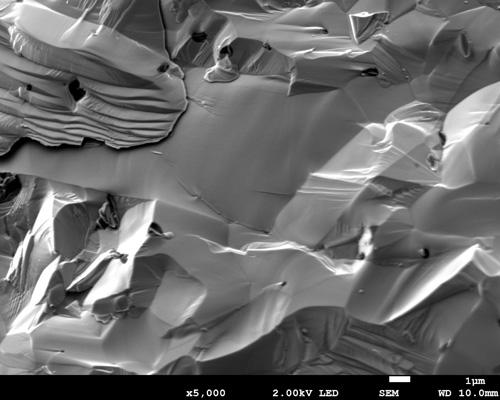

The activities on the synthesis and sintering of refractory ceramic compounds in vacuum at high temperatures (up to 2500°С) with the heating rate of up to 400°С/min are carried out in the department by the method of high-speed hot pressing (HSHP). The diagram for the HSHP method, HSHP unit, products based on silicon carbide (SiC), microstructure (SEM) of SiC ceramics obtained by the HSHP method are shown in the figure.

Department structure

- Organizational and Technical Support Group.

The group is engaged in the material, technical and organizational support of the department's work.

- Experimental Equipment Development Group.

The group's work is aimed at designing the equipment and tooling; research in the field of encapsulation of spent nuclear fuel and radioactive waste using ceramic protective materials; mathematical modeling of thermophysical processes for radionuclide migration in the geological massif of the RW disposal zone.

- Group of technological research on the processes of obtaining materials.

The group conducts materials research on ultradispersed powders and ceramic materials of oxide composition for RW isolation in nuclear power industry and production of new functional ceramics for other industries, development of various methods for the formation and sintering of ceramic prototypes, their analytical research and testing.

- Group of research and development of properties for ceramic materials.

The main directions of the group's activity are the development of radiation- and corrosion-resistant ceramic and glass-ceramic materials for RW conditioning; research on the structure, composition, physical and mechanical properties of the compounds obtained by the advanced methods of molding, sintering, hot pressing and hot isostatic pressing.

- Group for studying the effect of high pressures on materials.

The tasks of the group include studying the effect of high pressures on the physical, mechanical and operational properties of various materials, technical support for the operation of gasostatic equipment, hot vacuum pressing and heat treatment in various environments (vacuum, air, inert gases).

Publications

Employees

SAYENKO SERHIY YURIYOVYCH

Head of the Department “Gas Static and Plasma Technologies”

Doctor of Technical Sciences in specialty 21.06.01 – Environmental Safety

Senior Researcher in the specialty 05.02.01 – Materials Science

e-mail: sayenko@kipt.kharkov.ua, sergeysayenko2@gmail.com

Field of scientific interests:

development and materials science research of new protective ceramic and geopolymer materials for immobilization of liquid radioactive waste from nuclear power plants; scientific and administrative management of the scientific department for the implementation of the thematic plan under the Program of the NAS of Ukraine for the Development of Atomic Science and Technology, as well as management of the research of the NSC KIPT team participating in Euratom projects on radioactive waste management.

Activities outside the NSC KIPT:

- is a member of the editorial board of the journal “Nuclear and Radiation Safety”;

- is a member of the Euratom platform for the storage and geological disposal of radioactive waste.

SVETLYCHNYY EVGEN OLEKSANDROVYCH

Senior Researcher

Candidate of Technical Sciences in specialty 05.17.11 – Technology of Refractory Non-metallic Materials

Field of scientific interests:

development and materials science research of geopolymer and ceramic materials of oxide composition for radioactive waste isolation in nuclear power and creation of new functional ceramics for other industries, development of various methods of forming and sintering of ceramic prototypes, performing of analytical research and tests.

SHKUROPATENKO VOLODYMYR ANTONOVYCH

Senior Researcher

Candidate of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

Senior Researcher

e-mail: shkuropatenko@kipt.kharkov.ua

Field of scientific interests:

materials science research and development of technological processes for obtaining of geopolymer and ceramic mineral-like materials (apatites, pyrochlores, zircon, NZP ceramics) for use as matrices for safe storage/disposal of radioactive waste.

LOBACH KOSTYANTYN VYACHESLAVOVYCH

Researcher

Candidate of Technical Sciences in specialty 05.17.11 – Technology of Refractory Non-metallic Materials

e-mail: lobach0709@gmail.com

Field of scientific interests:

production and research of ceramic materials based on oxides, carbides, and borides, manufactured by high-speed hot pressing, vacuum hot pressing, and high-temperature sintering for the needs of nuclear energy.

Activities outside the NSC KIPT:

- Head of the Kharkiv branch of the Ukrainian Nuclear Society;

- Chair of the local organizing committee of the international scientific and technical conference named after V.M. Voevodin “Problems of Modern Nuclear Energy.”

ZYKOVA HANNA VENIAMINIVNA

Senior Researcher

Candidate of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

e-mail: zykova.anya@gmail.com

Field of scientific interests:

research of the formation of nanostructured ceramic materials and coatings using modern technologies. Research of the structure and properties of matrix insulating materials for the immobilization of radioactive waste in nuclear power and the creation of new functional materials for other industries. Development of optimal modes of modification of nanostructured materials and surfaces for structural, tribological and biomedical applications. Study of the structure and properties of ceramic materials using modern analytical methods.

Activities outside the NSC KIPT:

is a member of the editorial board of the journal «Scientific Journal of Gdynia Maritime University» (Gdynia, Poland).

KHOLOMEEV GENNADIY OLEKSANDROVYCH

Researcher

Field of scientific interests:

Development of materials, technologies and equipment for radioactive waste isolation. Conducting of research in the field of encapsulation of spent nuclear fuel and radioactive waste using ceramic protective materials. Mathematical modeling of thermophysical processes and radionuclide migration processes in the geological massif of the radioactive waste disposal area.