Work on the development of coating deposition methods has been carried out at NSC KIPT for more than 40 years in three departments of ISSPMT, one of which is the "Department of ion-plasma treatment of materials". Our specialists carry out research and development to ensure the creation of industrial methods, equipment and technologies for the deposition of coatings for various purposes using the vacuum-arc ion-plasma coating deposition. A short list of coatings deposited in our department includes hardening, protective and protective-decorative, self-supporting, anticorrosive, thermostable, barrier, antifriction, bactericidal and diamond coatings.

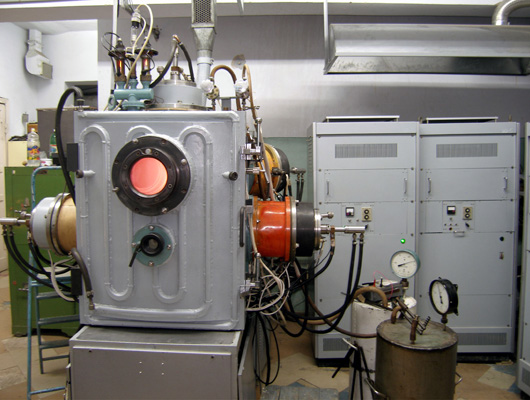

High-current vacuum-arc discharge is used to generate plasma flows. Controlling the parameters and composition of plasma flows ensures the implementation of ion-plasma cleaning processes, formation of base-coating transition zones, deposition of metal and composite coatings (oxide, nitride, carbide, etc.), and also allows ion implantation at energies up to tens of thousands of electron-volts.

In our Institute, directly from the developers, you can receive the new unique technologies and units developed to solve your specific tasks, as well as qualified recommendations and advice on their application. The Institute's specialists are the pioneers and leaders in the following areas:

- development of industrial technologies and equipment for functional coating deposition;

- synthesis of diamond-like coatings from the vacuum arc burning in carbon vapor;

- synthesis of polycrystalline diamond layers and coatings for various purposes from CO2-containing gas mixtures;

- development of plasma-optical systems for vacuum-arc plasma filtration from macroparticles (droplet fraction);

- creation of extended systems for generating metal plasma;

- development of equipment and processes for the production of thick (millimeters) coatings and parts by the vacuum-arc method;

- development and implementation of equipment and technologies for ion-plasma modification of the surface for nuclear structural materials.

In the department there are 2 laboratories, which include 1 corresponding member of NAS of Ukraine, 4 doctors of sciences and 8 PhDs.

The results of work are published in more than 1000 printed works. Click here to see a more detailed list.

Main directions of work:

- anti-corrosion and anti-erosion protection of construction materials operating under various conditions, including those exposed to high temperatures;

- increasing the durability and treatment quality for the shaping and cutting tools;

- development of anti-friction coatings on structural materials;

- development of products using the deposition of materials from the plasma or gas phase;

- creation of protective and decorative, bactericidal and antireflection coatings;

- development of a new class of materials (including nanostructured ones) in the form of coatings with unique characteristics and properties.

Major achievements

For the first time in the world, industrial technological processes and equipment were developed on the basis of vacuum-arc discharge to obtain hardening coatings for cutting and shaping tools. To ensure the wide use of the method, scientific and technological fundamentals of coating synthesis for various functional purposes were developed. The results are reflected in more than 10 monographs of the NSC KIPT specialists. The following was done by the NSC KIPT developers:

1. A license for the pilot technology and unit for producing TiN coatings was sold to the American company "Noble Field" (later Multi Arc Vacuum Systems Inc.). As a result, a new direction of coating deposition appeared in the world, which has been rapidly developing to the present day.

2. The production of more than 3,500 coating deposition units was organized, the development of appropriate technologies and improved equipment was carried out, and the training of operating personnel was provided.

3. The "wear-free" coating-based friction pairs were developed and successfully applied. This made it possible to solve the problem of operational life and accuracy of gyroscopes with a gas-dynamic suspension for the corresponding delivery systems.

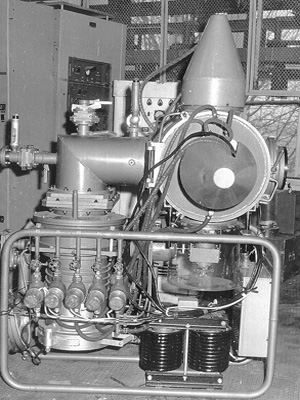

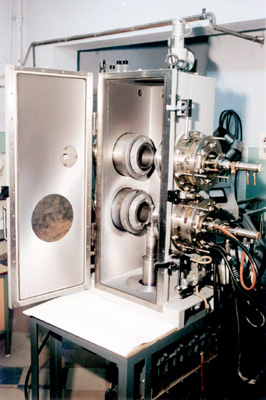

Bulat-3

Bulat-6

4. Anti-corrosion coatings and appropriate equipment were developed and successfully implemented at serial enterprises, which made it possible to ensure the service life of products made of highly chemically active materials from three to 25 years.

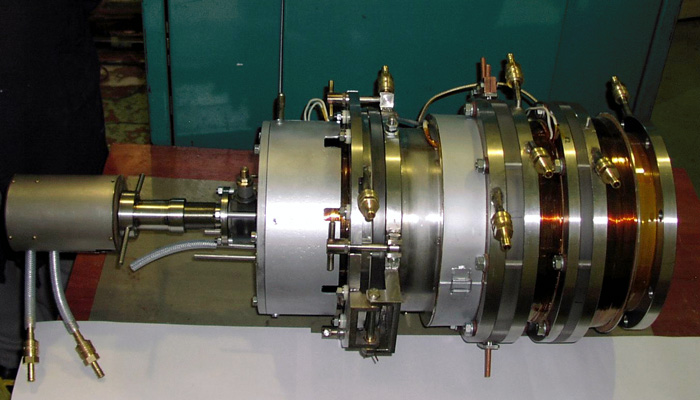

5. For the first time in the world, metal plasma separators were developed on the basis of plasma-optical systems. By now, such systems were developed with the efficiency of ≥ 85% (plasma transmission coefficient).

Diagram of the radial plasma flow formation system (RPFS):

1 ‑ cathode; 2 - anode; 3 - magnetic coil; 4 - substrate;

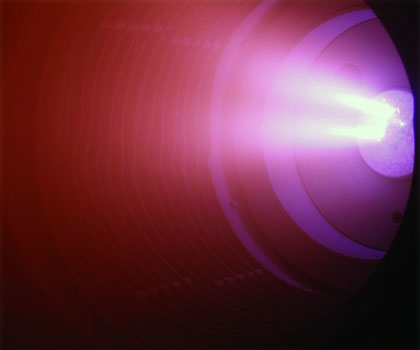

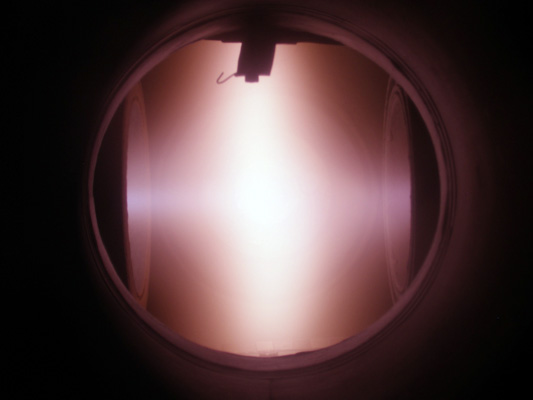

Photo of the discharge in RPFS

Magnetic island filter

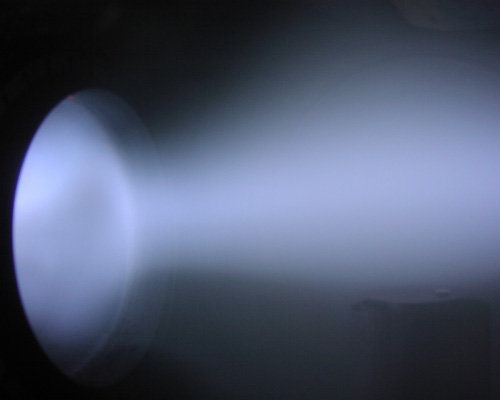

Photo of the discharge at the filter output

6. For the first time in the ISSPMThistory, one of such separators was licensed to a Dutch company (IHI Hauzer Techno Coating B.V.) and is a part of the equipment for coating deposition on the auto engine parts sold by the company.

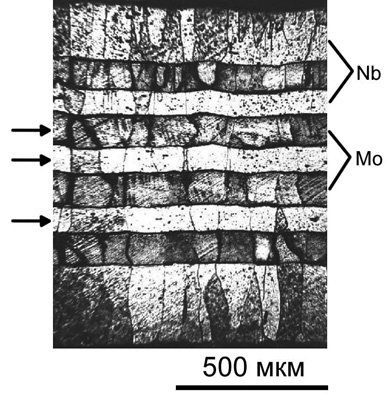

7. For the first time in the world, on the basis of vacuum-arc methods of coating deposition, the technology and appropriate equipment was developed for the production of hollow products in the form of Laval nozzles from the alternating layers of mixed materials.

8. By comparing the radiation resistance of nanostructured and microcrystalline materials, the theoretical conclusions on the increase in the radiation resistance of the alloys for nuclear power engineering were experimentally confirmed when creating such materials in a nanostructured state.

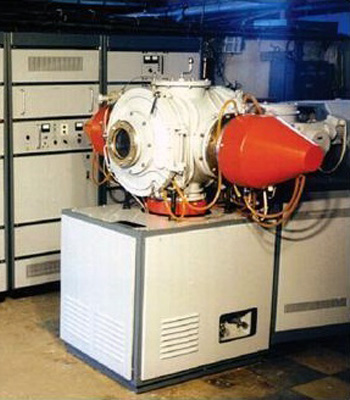

Bulat-MS

Finished nozzles

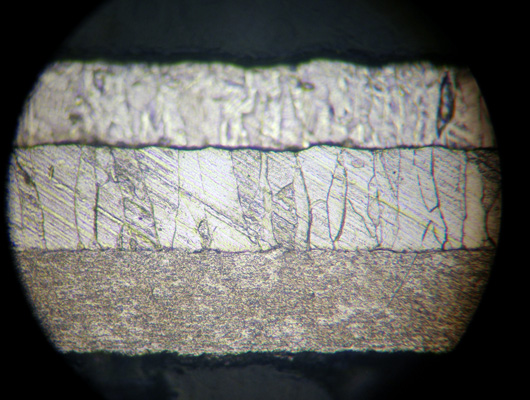

Cross-sectional view

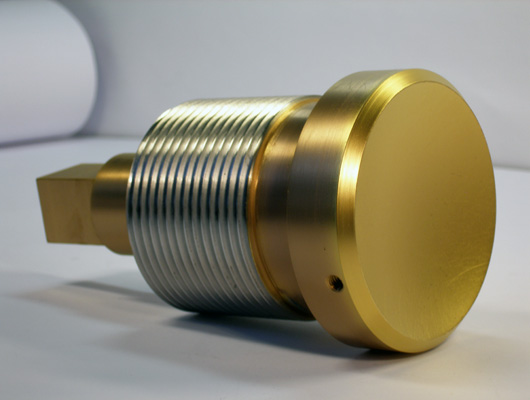

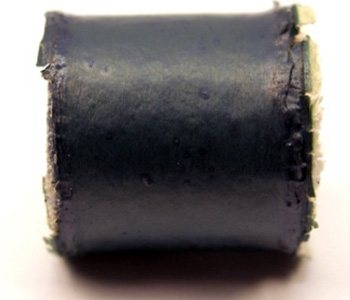

9. On the basis of the development results on diamond-like coatings, the technology and equipment were created, in-line production was established for the application of single and multi-layer diamond-like coatings with the hardness of up to 40 GPa on silicon carbide ring elements for dry gas seals (DGS) of compressor shafts for gas transportation systems and chemical industry. Under the contract with the Scientific and Production Company “Grace-Engineering” LLC in Sumy, in 2018, the coating was applied to 40 sets of DGS parts with the diameter from 120 to 225 mm. The technology and equipment were successfully introduced into production.

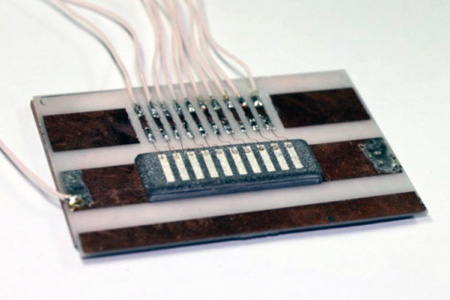

10. On the basis of fundamental research on the synthesis of diamond films from the gas phase, the technology and equipment were developed and the pilot batches of diamond plates with the resistivity of at least 1014 Ohm/cm and thickness of up to 400 μm are successfully manufactured. The plates are the key elements for the development of diamond-based high-temperature and radiation-resistant ionizing radiation sensors, which were successfully tested in the direct flow of the accelerator electrons.

Packaged detector

Coordinate-sensitive detector

11. By the order of JSC "Turboatom", a number of complex innovative technologies were developed (ion nitriding + coatings in one technological cycle), which can significantly increase the service life (1.5 times) and reliability of the components for steam distribution systems, exclude unstable "old-fashioned" environmentally hazardous furnace nitriding process. The technology was successfully implemented with the release of 100 different treated components, including massive ones, for operating turbines.

Penta installation

"Guide rod" (nitriding and TiN-coating)

"Turning joint" (nitriding and MoN-coating)

Ball joint: rod with MoN, sockets with TiN

Friction pair: axle with MoN, inserts with TiN

12. In response to the needs of JSC "Turboatom", the plant for the complex treatment of titanium blades for the last turbine stage (length 1300 mm, weight 36 kg) of NPP was developed, which allows avoiding the blade import from abroad.

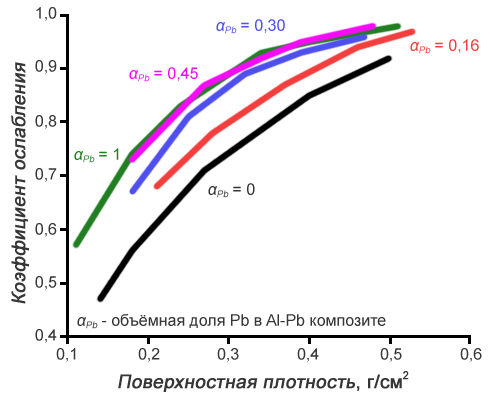

13. On the basis of fundamental research, a series of highly effective radiation-protective structures was developed, which provides a significant attenuation of radiation (by 30 - 40%) while maintaining the total thickness of the set of layers at the level of traditional aluminum. The development is supported by the international discovery patent.

Photo of a slice, top to bottom: Mo, Ti, substrate

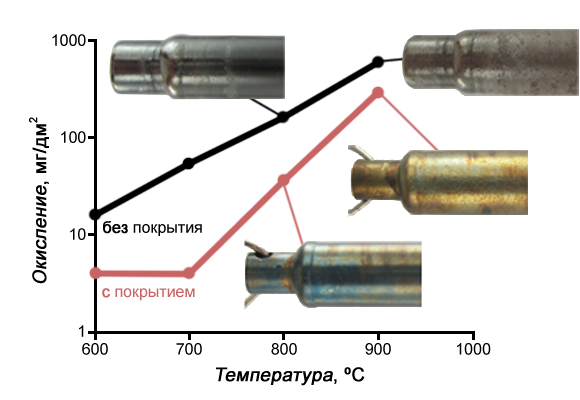

14. In order to prevent severe large-scale accidents such as Fukushima- in case of coolant loss in pressurized water reactors, highly effective barrier coatings for zirconium alloys were created to prevent the contact of the coolant with zirconium cladding and, as a consequence, the development of a vapor-zirconium reaction with the release of hydrogen as the temperature in the reactor is increased at the loss of coolant, both under operating conditions and in emergency situations. Test results for the samples with coated FE show high radiation, corrosion and cavitation resistance of protective layers, increased reliability of FE under operating conditions, and in emergency situations, the coatings are not destroyed at the temperature of 1100°С for at least 3600 s (usually, the FE zirconium tube is destroyed in 15 - 20 s under such conditions), which allows operating personnel to take emergency measures.

Zr-1Nb uncoated, 1020°C

Zr-1Nb coated, 1020°C

Coated E110, 1020°C

Zr-1Nb uncoated, 1100°C

Zr-1Nb coated, 1100°C

Coated E110, 1100°C

15. In general, the department has extensive experience in the development, manufacture and supply of the specialized equipment from far abroad, as well as adjustment in accordance with technical specifications. Over the past 15 - 20 years, the orders to the value of ∼ 5 million US dollars were completed; deliveries were made to the USA, Armenia, China, Holland and other countries.

Department structure

- Laboratory for ion-plasma treatment of materials.

Experimental and theoretical research and development in the field of physics and chemistry of vacuum-arc ion-plasma processes for the formation of functional coatings (protective, wear-resistant, corrosion and erosion-resistant, tribological, optical, decorative, etc.), surface modification of materials. Research and development of new technological processes and equipment for the deposition of ion-plasma coatings for various purposes, as well as processes for modifying the surface layers of materials by exposing them to high-energy ion flows.

- Laboratory of diamond and diamond-like coatings.

Comprehensive research in the physics and technology of the systems for the vacuum-arc sources of separated plasma and the sources based on gas discharge, as well as the processes for deposition of diamond and superhard coatings based on metals and carbon, including: research and development of the vacuum-arc sources of separated plasma, effective plasma sources on the basis of glow discharge for the deposition of diamond and diamond-like carbon coatings, polycrystalline diamond coatings, amorphous and nanostructured wear-resistant coatings for machine parts, tools and dielectrics; research of the mechanisms and optimization of the conditions for the transportation of vacuum-arc plasma in magnetic fields; simulation of the processes for metastable structure synthesis, occurrence of residual stress in condensates under the conditions of ion bombardment of the film growth surface.

Publications

Employees

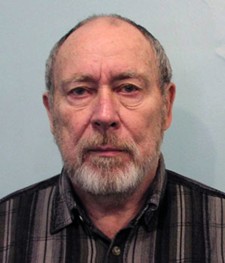

BILOUS VITALIY ARSENTIYOVYCH

Deputy Director of ISSPMST NSC KIPT for Scientific Work

Corresponding Member of the National Academy of Sciences of Ukraine

Head of the Department “Ion-plasma Processing of Materials”

Doctor of Technical Sciences in specialty 05.02.01 – Materials Science

Senior Researcher

e-mail: belous@kipt.kharkov.ua

Field of scientific interests:

nanostructured anti-corrosion, anti-erosion and barrier coatings on products made of zirconium alloys; nuclear fuel indifferent to emergency situations; increasing the operational characteristics of parts and assemblies of power engineering products; bactericidal coatings for medical purposes with control of the process of manifestation of bactericidal activity; vacuum-arc discharges under low pressure conditions.

KOMAR ANATOLIY ANATOLIYOVYCH

Deputy Head of the Department of “Ion-Plasma Processing of Materials”

e-mail: komar@kipt.kharkov.ua

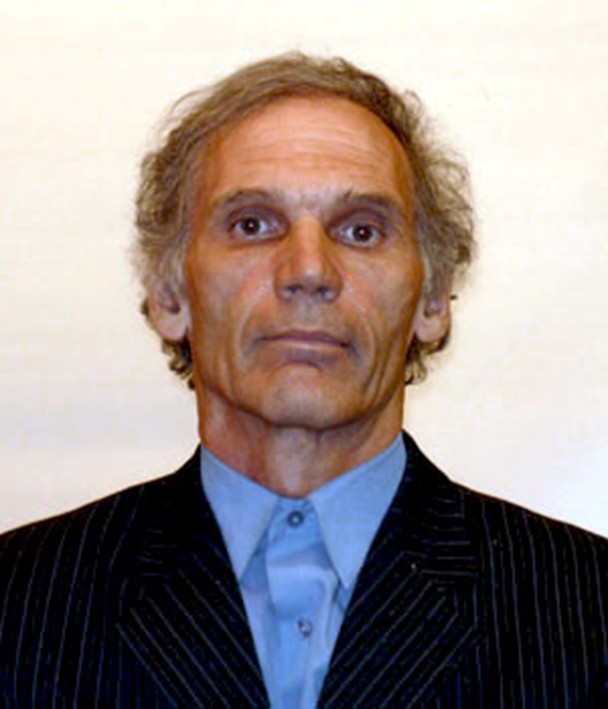

STRELNYTSKYY VOLODYMYR EVGENOVYCH

Head of the Laboratory “Diamond and Diamond-Like Coatings”

Doctor of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

Senior Researcher

Ph. +38(057) 335-65-61, +38 067 579 34 13

e-mail: strelnitskij@kipt.kharkov.ua

Field of scientific interests:

structure and properties of superhard carbon, nitride and carbide coatings; vacuum-arc sources of filtered plasma; technology for obtaining coatings by CVD and PECVD methods; physical foundations of obtaining coatings from plasma flows.

KUPRIN OLEKSANDR SERHIYOVYCH

Head of the Laboratory “Ion-plasma Processing of Materials”

Candidate of Technical Sciences in specialty 01.04.07 – Solid State Physics

Senior researcher in specialty 104 Physics and Astronomy

Laureate of the NAS of Ukraine Prize for Young Scientists for the cycle of works “Improvement of Zirconium Alloy Products by Ion-Plasma Modification” (co-authored with G.M. Tolmachova), 2014.

e-mail: kuprin@kipt.kharkov.ua

Field of scientific interests:

development and research of vacuum-arc coatings to protect fuel tubes made of zirconium alloys from oxidation in air and water vapor.

KALINICHENKO ALEXANDER IVANOVICH

Leading Researcher

Doctor of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

Senior Researcher

Ph. +38(057) 335-65-61, +38 067 900 95 18

e-mail: aikalinichenko@kipt.kharkov.ua

Field of scientific interests:

theoretical research in the following areas: radiation-acoustic effects in solids; processes of structure formation, transfer and destruction in a solid upon irradiation with ions or neutrons; properties of coatings deposited by plasma-ion methods.

RESHETNYAK OLENA MYKOLAIVNA

Leading Researcher

Doctor of Physical and Mathematical Sciences in specialty 01.04.07 – Solid State Physics

Senior Researcher in the specialty 01.04.07 – Solid State Physics

Ph. +38(057) 335-62-10, +38 067 683 05 69

e-mail: reshetnyak@kipt.kharkov.ua

Field of scientific interests:

physical materials science; physical foundations of PVD and CVD methods of deposition of functional coatings; structure and properties of nanocrystalline films; X-ray diffractometry; X-ray fluorescence analysis.

VASYLIEV VOLODYMYR VASYLOVYCH

Senior Researcher

Candidate of Technical Sciences in specialty 01.04.07 – Solid State Physics

Ph. +38(057) 335-66-32, +38 067 103 94 13

e-mail: vladimir.vasyliev@ukr.net

Field of scientific interests:

development of highly efficient sources of filtered vacuum-arc plasma; technologies for the synthesis of wear-resistant coatings.

LUCHANINOV OLEKSANDR ANDRIYOVYCH

Senior Researcher

Candidate of Physical and Mathematical Sciences, specialty 01.04.08 – Plasma Physics and Chemistry

Senior Researcher

e-mail: luchaninov@kipt.kharkov.ua

Field of scientific interests:

sources of low-temperature plasma; physics and technology of deposition of superhard coatings and study of their properties; interaction of accelerated particles with a solid.

TOLMACHOVA HALYNA MYKOLAYIVNA

Senior Researcher

Candidate of Technical Sciences in specialty 01.04.07 – Solid State Physics

Senior Researcher in the Field of 104 Physics and Astronomy

Scholarship holder of the National Academy of Sciences of Ukraine for young scientists in 2013 and 2017

Laureate of the NAS of Ukraine Award for Young Scientists for a series of works entitled “Improvement of zirconium alloy products by ion-plasma modification” (co-authored with O.S. Kuprin) in 2014; Winner of the NAS of Ukraine Award for Young Scientists for the best scientific work in 2018.

Ph. +38(057) 335-62-64, +38 097 391 69 26

e-mail: tolmachovagn@kipt.kharkov.ua

Field of scientific interests:

investigation of the physical and mechanical properties of promising materials and protective coatings for use in various fields of mechanical engineering and nuclear energy, employing the nanoindentation method.

AKSONOV DMYTRO SERGIYOVYCH

Researcher

Candidate of Technical Sciences in the specialty 05.03.07 – Processes of Physical and Technical Treatment

e-mail: dcaksyonov@kipt.kharkov.ua

Field of scientific interests:

vacuum-arc deposition of multicomponent coatings; calculation of parameters of macroparticle flows (droplet fraction) of vacuum-arc plasma; modeling, optimization and tuning of the transporting properties of curvilinear magnetoelectric filters.